Precision Laser Cutting Service in North West UK

Looking for fast, precise, and high-quality laser cutting? Our Laser Cutting Service is designed to deliver exceptional accuracy and efficiency, making it the perfect choice for engineering, industrial, and architectural applications. Whether you need a one-off prototype or a high-volume production run, here at North West Water Jetting, we’ve got you covered.

Our laser service perfectly complements our waterjet cutting capabilities, but for thinner materials. Our laser cutting is the faster and more cost-effective option. With clean, sharp edges and minimal material waste, our process ensures superior results every time.

What Can We Laser Cut?

We specialise in cutting a variety of different metals, these include:

- Mild Steel – up to 25mm

- Stainless Steel (304 & 316) – up to 20mm

- Aluminium – up to 15mm

- Brass – up to 10mm

- Copper – up to 8mm

For thicker materials, our waterjet cutting service offers the ultimate flexibility, ensuring clean and precise results.

LASER CUTTING CAPABILITIES

Our laser cutting service is optimised for high-speed, high-accuracy cutting of thin to medium-gauge metals, making it ideal for production work and detailed components.

Typical laser cutting capabilities include:

- Maximum sheet size: 3000mm x 1500mm

- High-speed cutting for efficient production

- Clean, sharp edges with minimal finishing required

- Excellent repeatability for batch production

- Minimal material waste

Our laser cutting service is best suited to thinner materials where speed, accuracy, and cost efficiency are key.

Typical Laser Cutting Specifications

| Material | Maximum Thickness | Typical Accuracy |

|---|---|---|

| Mild Steel | Up to 25mm | ±0.1mm |

| Stainless Steel (304 / 316) | Up to 20mm | ±0.1mm |

| Aluminium | Up to 15mm | ±0.1mm |

| Brass | Up to 10mm | ±0.15mm |

| Copper | Up to 8mm | ±0.15mm |

Talk to our expert team today

Serving the North West & Beyond

From Manchester, Liverpool, Preston, Skelmersdale, and throughout the North West, we offer industry-leading laser cutting with rapid turnaround times. If you can design it, we can laser cut it!

Our Advanced Laser Technology

We use an Amada Laser with a 3000mm x 1500mm bed size, featuring shuttle tables for maximum efficiency. This allows us to handle both small one-off projects and large production batches with ease.

Why Choose Us?

✅ Speed & Accuracy – Precise cuts with minimal waste

✅ Versatility – Serving multiple industries with various materials

✅ Reliability – Consistent quality and fast lead times

✅ Local Expertise – Trusted by businesses across the North West

INDUSTRIES & APPLICATIONS

Our laser cutting service is trusted by businesses across a wide range of industries where speed, accuracy, and repeatability are essential.

We regularly provide laser cutting for:

Engineering & Manufacturing

Precision components, brackets, panels, and production parts.

Automotive & Motorsport

Custom parts, mounting plates, and prototype components requiring tight tolerances.

Architectural & Construction

Decorative metal panels, screens, brackets, and bespoke fabricated features.

Electrical & Enclosures

Panels, cut-outs, and housings produced accurately and efficiently.

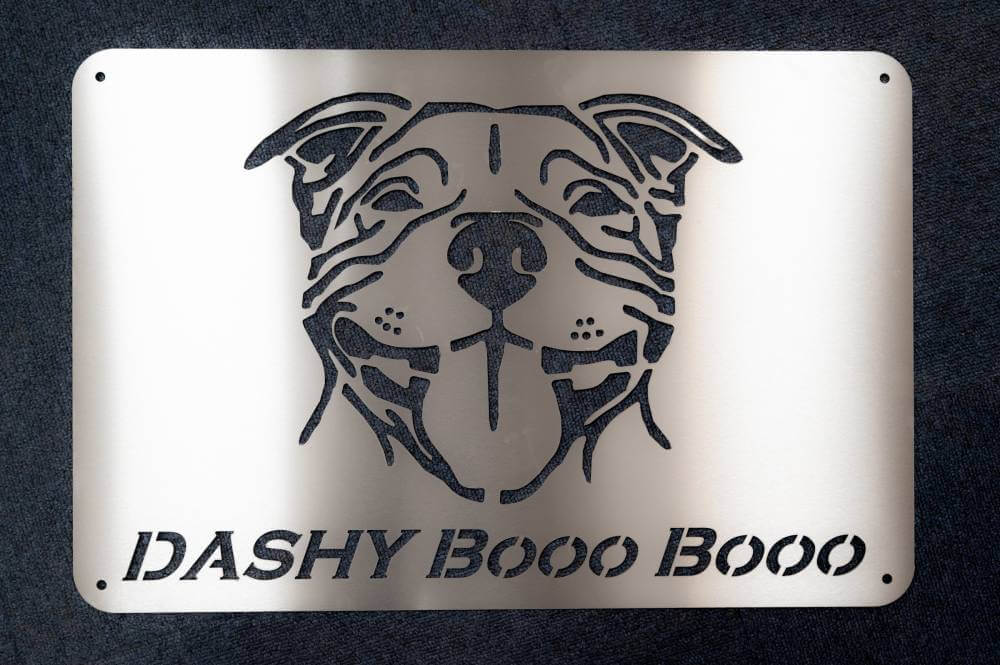

Signage & Fabrication

Lettering, logos, panels, and decorative metalwork.

From one-off prototypes to high-volume production runs, our laser cutting service delivers consistent quality and fast turnaround times.

LASER CUTTING VS WATERJET CUTTING – WHICH IS RIGHT FOR YOUR PROJECT?

Laser cutting and waterjet cutting both offer high levels of precision, but each process is suited to different applications.

Laser cutting is ideal when:

- Cutting thin to medium-gauge metals

- Speed and efficiency are priorities

- Producing high-volume batches

- Fine detailing on thinner materials is required

Waterjet cutting is better suited when:

- Cutting very thick materials

- Working with heat-sensitive materials

- Cutting reflective metals such as copper or brass

- Material integrity is critical, with no heat-affected zone

Because we offer both laser cutting and waterjet cutting, we can advise on the most efficient and cost-effective solution for your application.

Laser Cutting – Frequently Asked Questions

How accurate is laser cutting?

Laser cutting offers excellent accuracy and repeatability, making it ideal for precision components, detailed profiles, and batch production where consistency is essential.

What materials can you laser cut?

We laser cut a range of metals including mild steel, stainless steel (304/316), aluminium, brass, and copper within thickness limits.

What file formats do you accept?

We can work from common CAD formats such as DXF and DWG. If you don’t have a suitable drawing, our CAD design service can help turn your idea into a cut-ready file.

Is laser cutting suitable for high-volume production?

Yes. Laser cutting is well suited to repeat production runs thanks to its speed, accuracy, and consistent results—ideal for batch parts and production components.

Can you cut thicker materials?

Laser cutting is most efficient on thin to medium-gauge metals. For very thick materials, our waterjet cutting service is often the best option for clean and precise results.

Do you offer nationwide delivery?

Yes. While we are based in the North West, we supply customers across the UK and can arrange reliable nationwide delivery.

Get in Touch Today!

📞 Call us now on 01257 650050

📧 Email us at sales@northwestwaterjet.co.uk

Let’s bring your designs to life—fast, accurate, and hassle-free!