What Materials Lend Themselves to the Different Cutting Methods?

At Northwest Waterjet, we specialise in high-precision waterjet and laser cutting, delivering exceptional accuracy and efficiency.

Both cutting methods offer unique benefits depending on the material in question, but how do you know which is the right choice for your project?

We’re often asked how waterjet cutting compares to laser cutting, especially when working with specific materials.

This blog explores which materials are best suited to each method, helping you make an informed decision for your next job.

Understanding the Cutting Methods

Waterjet Cutting

Waterjet Cutting uses an ultra-high-pressure stream of water, often mixed with abrasive particles, to erode the material. It’s a cold-cutting method, meaning no heat is applied, making it ideal for sensitive or layered materials.

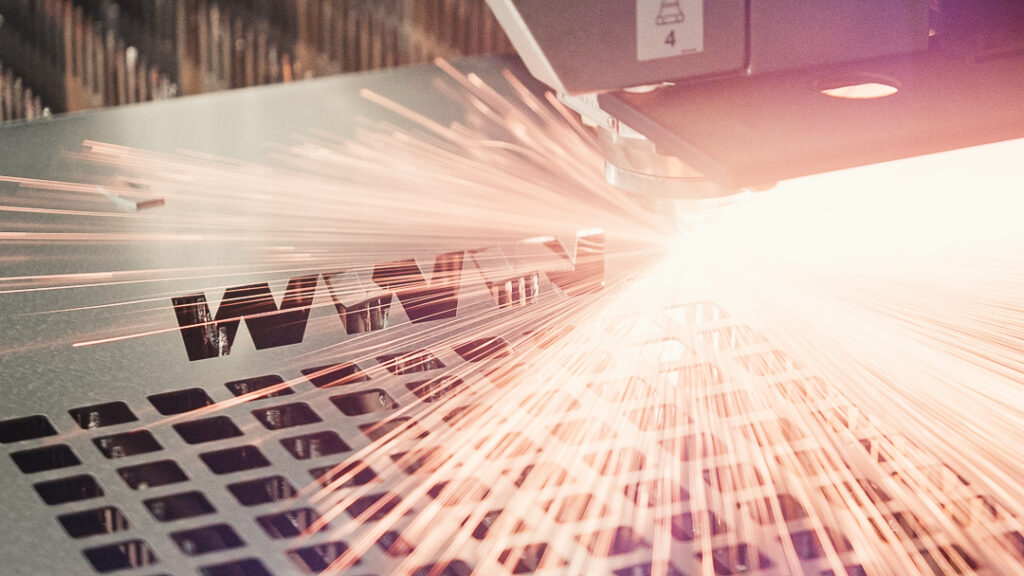

Laser Cutting

Laser Cutting uses a concentrated beam of light to melt or burn through materials. It’s extremely precise and fast, particularly effective on thin, uniform materials.

Which Materials Work Best with Waterjet Cutting?

Waterjet cutting is extremely versatile, capable of cutting through a wide range of materials, especially those that don’t respond well to heat.

Ideal Materials for Waterjet Cutting:

- Metals: Stainless steel, aluminium, copper, brass, thick or reflective metals that laser cutters may struggle with.

- Stone & Tile: Granite, marble, ceramic, great for architectural applications.

- Glass: Including some forms of laminated and decorative glass.

- Rubber & Foam: Waterjet offers clean, precise cuts without compressing the material.

- Composites: Carbon fibre, fibreglass, layered materials.

- Plastics: Especially those that emit toxic fumes when laser cut (e.g. PVC, polycarbonate).

Because it doesn’t generate heat, waterjet cutting avoids issues like warping, hardening, or burning around the edges.

Which Materials Are Better Suited to Laser Cutting?

Laser cutting is best for thin, consistent materials where speed and intricate detail are required. It’s ideal for mass production or decorative work.

Ideal Materials for Laser Cutting:

- Mild Steel – up to 25mm

- Stainless Steel (304 & 316) – up to 20mm

- Aluminium – up to 15mm

- Brass – up to 10mm

- Copper – up to 8mm

However, laser cutting isn’t suitable for highly reflective metals, thick materials, or plastics that release toxic gases when burned.

For thicker materials, our waterjet cutting service offers the ultimate flexibility, ensuring clean and precise results.

Waterjet vs Laser: Which One Should You Use?

Cuts through thick materials

Waterjet cutting: Yes

Laser cutting: No

Suitable for heat-sensitive materials

Waterjet cutting: Yes

Laser cutting: No

Handles reflective metals

Waterjet cutting: Yes

Laser cutting: Limited

Intricate designs on thin materials

Waterjet cutting: Yes

Laser cutting: Yes

Clean finish on plastics and acrylics

Waterjet cutting: Yes

Laser cutting: N/A

Cuts soft materials like foam or rubber

Waterjet cutting: Yes

Laser cutting: No

High-speed production for thin sheets

Waterjet cutting: Moderate

Laser cutting: Excellent

Need Expert Advice on Material Compatibility?

Choosing the right cutting method can be the difference between a flawless finish and a compromised result.

At Northwest Waterjet, we help businesses across the UK find the ideal solution for their cutting needs, completing the job with precision and care.

Contact our team for honest advice, competitive quotes, and high-quality results.