What Is Heat Distortion?

When working with high-precision manufacturing, one of the biggest challenges engineers face is ensuring materials remain stable during cutting. Heat-based cutting methods can cause heat distortion, which can create problems.

In this guide, we’ll explain what heat distortion is, why it occurs, and how alternative methods such as waterjet cutting provide a solution for industries where precision and material integrity are essential.

Understanding Heat Distortion

Heat distortion happens when materials are exposed to extreme heat during cutting or forming. The high temperature causes localised expansion, and as the material cools, it contracts unevenly.

The result can be:

- Warping or bending of the material

- Weakened areas

- Micro-cracks

- Altered surface finish

- Inconsistent dimensions and tolerances

For industries that demand absolute precision, such as aerospace, automotive, and medical manufacturing, even the slightest distortion can compromise the quality of the final product.

Why Does Heat Distortion Occur?

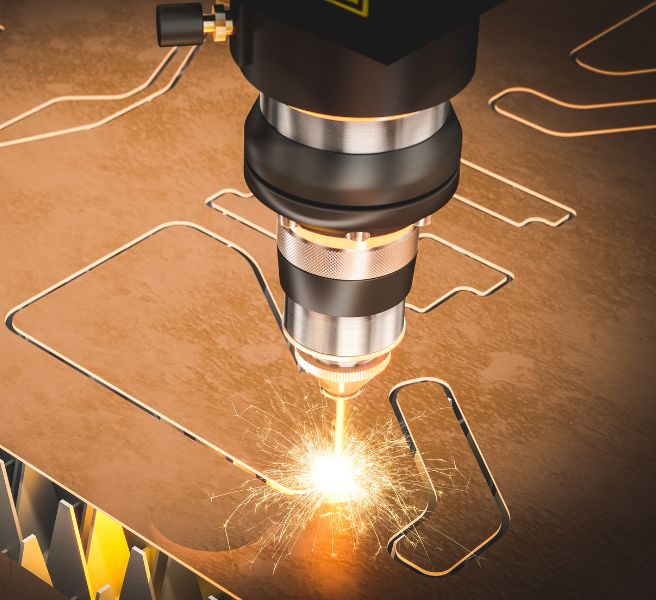

Heat distortion occurs during heat-intensive cutting methods like plasma cutting, welding, and sometimes laser cutting. Material type, cutting speed, and material thickness all play a role in how much heat is absorbed and how the material responds.

That said, it’s important to recognise that laser cutting technology has advanced significantly. With the right settings, materials, and machine controls, distortion can be minimised or avoided altogether. Laser cutting often remains an efficient and cost-effective option for many projects.

The Benefits of Our Cutting Methods

We provide both waterjet and laser cutting because each method has unique advantages.

Waterjet Cutting Benefits

Unlike thermal processes, waterjet cutting uses a high-pressure stream of water, mixed with abrasives, to cut materials without introducing heat. This cold-cutting method removes the risk of distortion and heat-affected zones (HAZ).

- No heat-affected zones: making it perfect for materials prone to heat distortion.

- Material versatility: cuts metals, plastics, acrylics, wood, ceramics, stone, and even foam for case inserts

- Sustainability: reduced waste, no toxic fumes, and efficient material use.

Waterjet cutting is often chosen when the material properties need to remain unchanged, or when cutting very thick or heat-sensitive materials.

Laser Cutting Benefits

- Speed and efficiency: ideal for high-volume production.

- Cost-effective: particularly for thinner metals and sheet materials.

- Accuracy: capable of delivering fine detail and clean edges.

Laser cutting is an excellent choice when speed, cost, and precision are key, particularly for sheet metal work in industries such as signage, architecture, and product manufacturing.

Choosing the Right Method for the Job

Heat distortion is a consideration in manufacturing, but it doesn’t mean one process is better than another. The key is selecting the right technology for the requirements of each project.

- For speed, cost efficiency, and clean finishes on thin materials, laser cutting is often the best option.

- For thick, heat-sensitive, or complex materials, waterjet cutting is usually more suitable.

By offering both services, Northwest Waterjet helps clients make the most informed choice for their project. Our team will assess your project requirements and recommend the most efficient, cost-effective, and precise solution, whether that’s laser or waterjet. Get in contact to discuss your next project.