Reducing Metal Waste with High-Precision Cutting Techniques

In manufacturing, efficiency and sustainability go hand in hand. Reducing material waste has become a key focus for industries. By using precise cutting methods like laser cutting and waterjet cutting, we help manufacturers achieve tighter tolerances, cleaner cuts, and greater material yield, helping to reduce environmental impact and wasted materials.

The Cost of Metal Waste

Metal waste isn’t just an environmental issue; it’s an economic one. Every offcut, burr, or misaligned cut means lost raw material, extra processing time, and higher production costs. Traditional cutting methods, such as mechanical sawing or plasma cutting, often lead to excess waste due to heat distortion, wider kerf widths, and inconsistencies.

By contrast, high-precision cutting technologies like waterjet and laser cutting make it possible to maximise material usage, reduce scrap, and create intricate components.

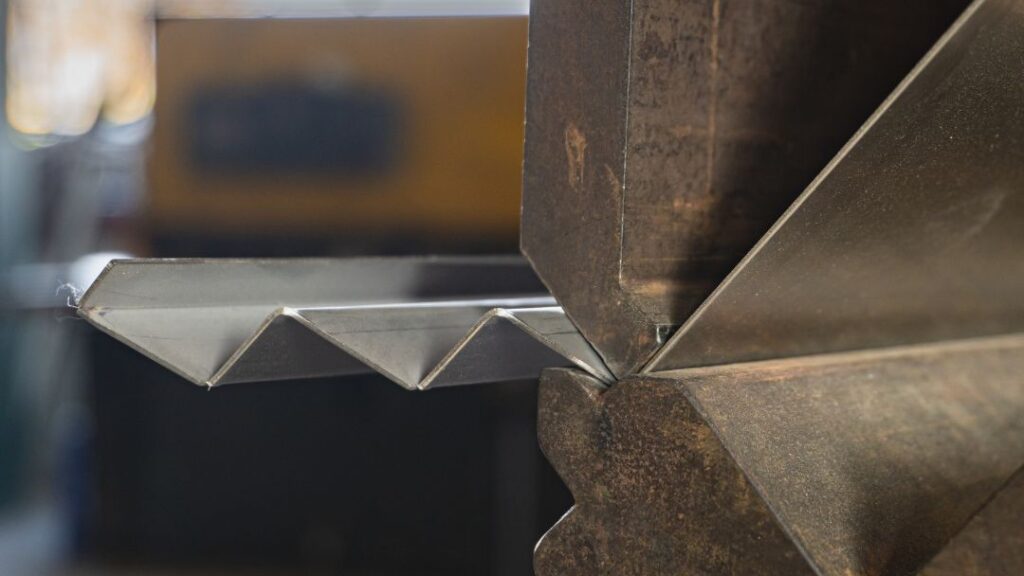

High-Precision Waterjet Cutting: Accuracy Without Heat

Waterjet cutting has gained a reputation for being one of the most accurate and sustainable metal cutting methods available. Using a fine stream of water mixed with an abrasive, it can cut through a wide range of materials such as stainless steel, aluminium, and titanium with exceptional precision.

Because it’s a cold-cutting process, waterjet cutting eliminates heat-affected zones (HAZ), preventing warping or structural changes in the metal. This means less need for post-processing and less wasted material.

Our waterjet systems can cut complex shapes with millimetre precision, ensuring every sheet of metal is used to its full potential.

Laser Cutting: Fast, Clean, and Efficient

For metals that benefit from thermal cutting, laser cutting offers speed and consistency. Modern laser cutting machines use a highly focused beam of light to cut through metal sheets with remarkable accuracy and clean edges.

The narrow kerf width of laser cutting minimises material loss, while computer-controlled software optimises the arrangement of parts on each sheet. This planning reduces offcuts, allowing manufacturers to make the most of every piece of material.

Laser cutting delivers the precision required for tight tolerances and repeatable results, a key factor in keeping waste to a minimum.

CNC Folding & CAD Design: Precision in Every Bend and Line

Integrating CNC folding and CAD design workflows allows us to deliver components that meet rigorous tolerances, again minimising waste and reducing reworks.

CNC Folding

Our CNC folding systems can produce consistent bends to the required angle. Because the process is digitally controlled, it reduces human error and ensures each part is folded identically to specification. This accuracy means that fewer test pieces or iterations are needed, helping to lower material waste.

Moreover, with CNC folding, we can sequence bends in the optimal order, prevent collision or interference, and reduce handling. This streamlines workflow, reducing scrap and speeding up production.

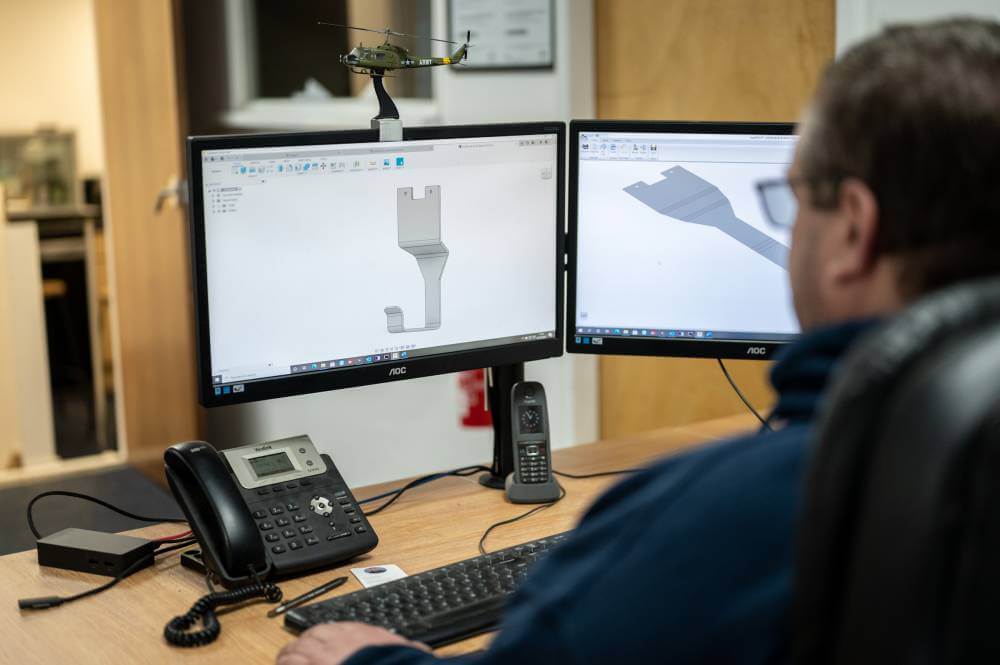

CAD Design

We use CAD software to create precise 3D models of each part, including bend lines and tolerances. From these models, nesting and layout optimisation can be carried out so that parts are arranged on the raw material sheets in a way that maximises yield and minimises offcuts.

Our software also allows virtual simulation for visualising fold sequences, helping us to avoid mistakes, reducing scrap, rework, and associated costs.

Synergising Cutting, Folding & Design

By combining CNC folding, CAD design, and precise cutting methods. We offer an integrated workflow, which ensures:

- Optimised use of raw material (less waste)

- Predictable, consistent part quality

- Faster turnarounds due to fewer errors or retakes

- Cost savings

- Lower energy usage through efficient processes

- More sustainable manufacturing overall

Our processes are designed to be as environmentally responsible as they are efficient. Every project is approached with waste reduction and resource optimisation in mind.

Why Choose Northwest Waterjet?

Based in the North West of England, we work with clients across a wide range of industries to deliver reliable, high-quality cutting services. Our team combines technical expertise with cutting-edge machinery to achieve outstanding results on every project.

As industries push towards greater sustainability, precision cutting has become an essential part of responsible manufacturing. By investing in advanced waterjet and laser cutting technology, companies can drastically reduce metal waste, improve efficiency, and lower production costs.

We’re proud to support UK manufacturers with precision-engineered cutting solutions that combine innovation, accuracy, and sustainability. Get in touch for more information.