What is CNC Folding and How Does It Work?

CNC folding is a vital process used in precision manufacturing and metal fabrication. But what exactly is CNC folding, and why is it so important in achieving a high-quality finish?

Our CNC folding services are tailored to deliver exceptional results, especially for clients who demand accuracy, speed, and professional standards in metal forming.

What is CNC Folding?

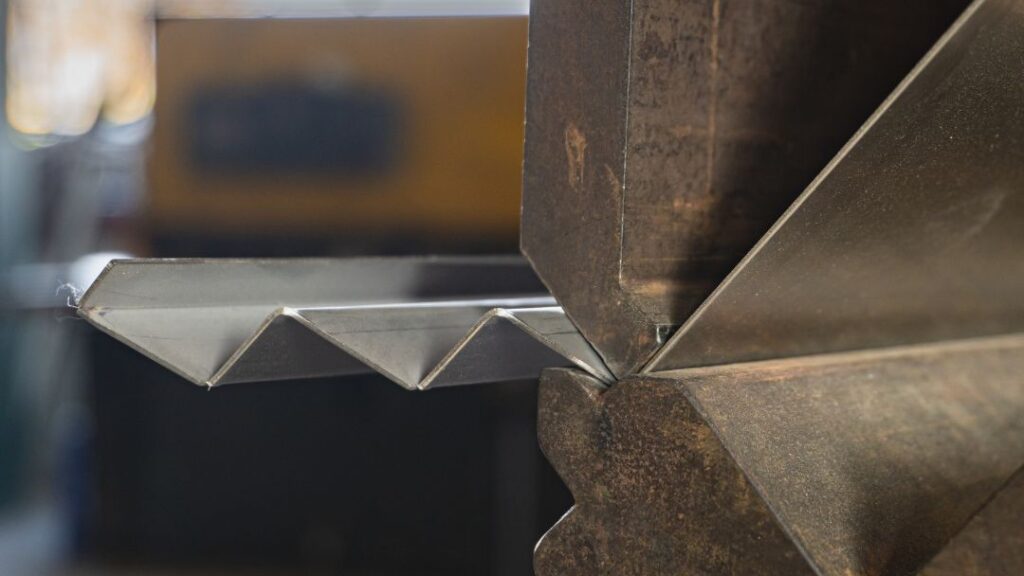

CNC folding (or CNC press braking) is a computer-controlled process used to bend or fold sheet metal into specific angles and shapes. CNC stands for Computer Numerical Control, meaning the machine uses pre-programmed instructions to move and fold metal with pinpoint accuracy.

This automated folding process ensures precision across multiple folds, minimises human error, and boosts efficiency, making it ideal for both one-off prototypes and large-scale production runs.

How Does CNC Folding Work?

The CNC folding process involves the following steps:

- CAD Design & Programming: Engineers create a digital model of the component using CAD software. This design is then converted into CNC machine instructions.

- Placement: The metal sheet is placed on the folding machine’s bed, aligned precisely to match the programmed specifications.

- Bending: A press brake applies force to bend the sheet metal to the required angle. The CNC controller adjusts pressure, angle, and position automatically.

- Final Checks: The folded part is inspected to ensure it meets tolerance requirements.

CNC folding delivers extremely tight tolerances and consistent results.

Why Choose Our CNC Folding Service?

- High-precision bending: CNC folding ensures accuracy on every single fold.

- Fast turnaround times: Automated programming and operation significantly reduce lead times compared to manual folding.

- Consistent Quality: Perfect for repeat jobs where uniformity matters.

- Versatility: Capable of folding a wide range of materials

- Cost-effective production: Limited material waste and efficient production, saving you money.

- Tailored solutions: We can handle projects of any size, whether you need prototypes, small batches, or large production runs.

- Northwest Waterjet offers one-stop fabrication services, we offer a fully integrated solution with our laser cutting, waterjet cutting, and CNC folding all under one roof,

CNC Folding vs. Other Methods

Unlike manual or semi-automated folding, CNC machines can deliver a higher level of detail and precision.

When combined with technologies like water jet cutting or laser cutting, CNC folding completes the fabrication workflow. At North West Waterjet, we not only provide water jet cutting and laser cutting but also offer in-house CNC folding, giving you full-service manufacturing under one roof.

Industries That Benefit from CNC Folding

- Construction & Architecture

- Automotive Engineering

- Custom Manufacturing

- Aerospace Components

If your project requires sharp bends and accurate folds, CNC folding is the most reliable method to ensure results that stand the test of time.

Get in Touch for CNC Folding Services

Located in the North West of England, we support clients across the UK with fast, affordable, and professional CNC folding solutions as well as Waterjet and laser cutting. Contact Northwest Waterjet today to see how we can bring your next project to life!