Top 5 Advantages of Laser Cutting for Precision Manufacturing

In modern manufacturing, accuracy, speed, and repeatability are really important. As industries across the UK look for ways to streamline production while maintaining exceptional quality, laser cutting continues to stand out as one of the most reliable and versatile fabrication methods available.

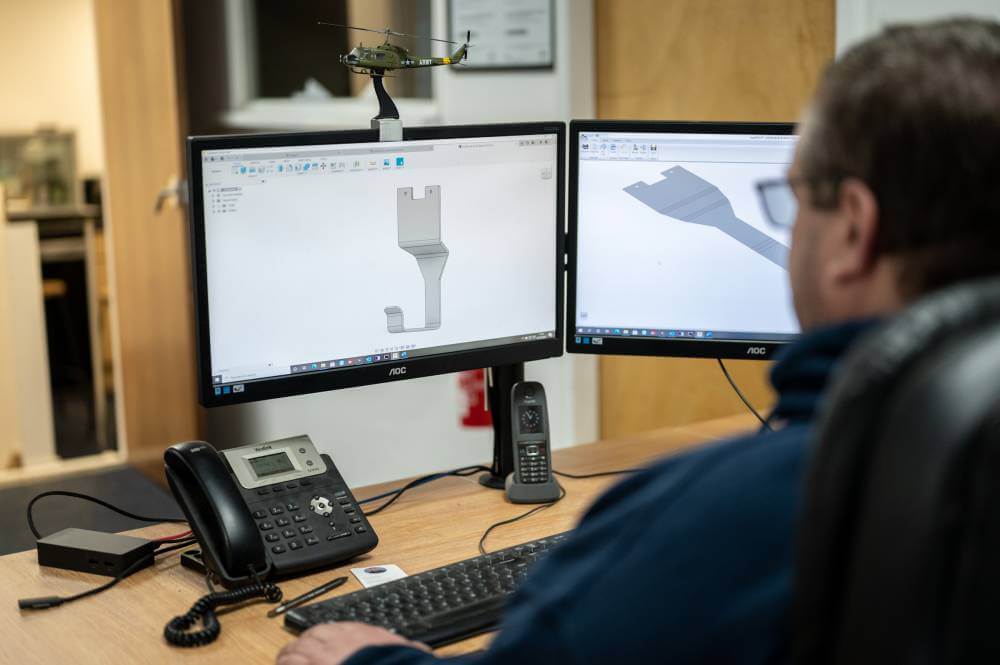

Our advanced laser cutting service supports manufacturers across automotive, engineering, sign making, architecture, product development, and more, providing an efficient way to turn CAD designs into perfectly cut components.

Here are the top five reasons why laser cutting remains a leading choice for precision manufacturing.

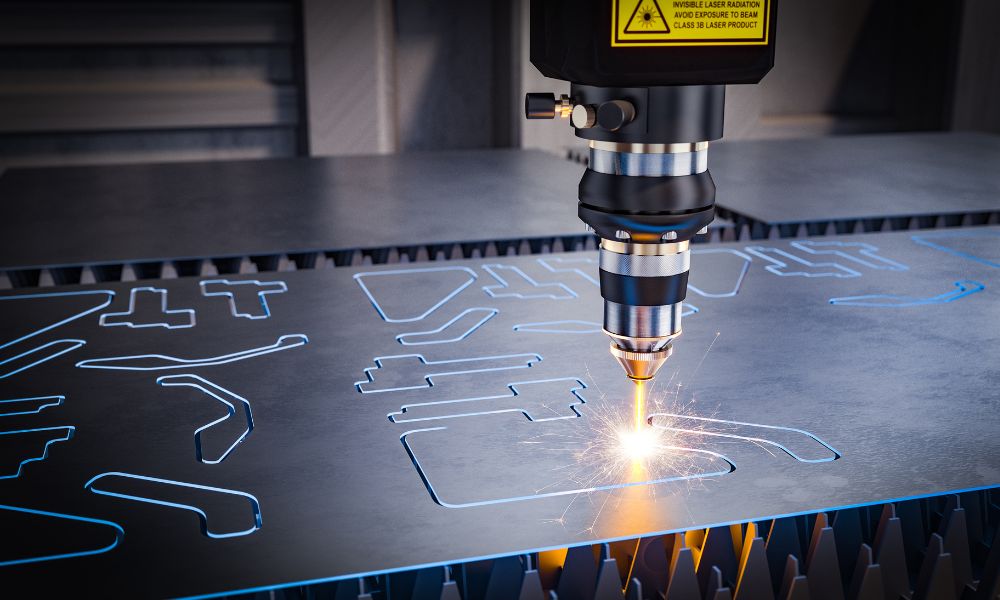

1. Exceptional Accuracy and Clean Finishes

Laser cutting produces extremely narrow kerf widths and tight tolerances, allowing manufacturers to achieve intricate shapes, detailed patterns, and sharp internal corners with ease. Because the laser is so precise, the heat-affected zone is minimal, resulting in clean edges and reduced finishing work.

This level of accuracy allows laser profile cutting to be used for everything from bespoke one-off parts to highly detailed production runs.

2. Speed and Efficiency for High-Volume Production

Laser cutting is faster than many traditional cutting methods, especially when working with thin to medium-thickness metals. High-speed cutting keeps projects moving efficiently and supports fast turnaround for both prototypes and full-scale manufacturing runs.

3. Versatility Across Materials and Applications

Laser cutters work exceptionally well with a wide range of metals, including:

- Mild Steel – up to 25mm

- Stainless Steel (304 & 316) – up to 20mm

- Aluminium – up to 15mm

- Brass – up to 10mm

- Copper – up to 8mm

This versatility gives manufacturers freedom in design and product development, providing a reliable solution capable of handling complex geometries and demanding tolerances.

However, not every material is suitable for laser cutting, particularly heat-sensitive or reflective materials. If the material you require cannot be laser cut, we also offer high-precision waterjet cutting. This cutting process handles most materials, including:

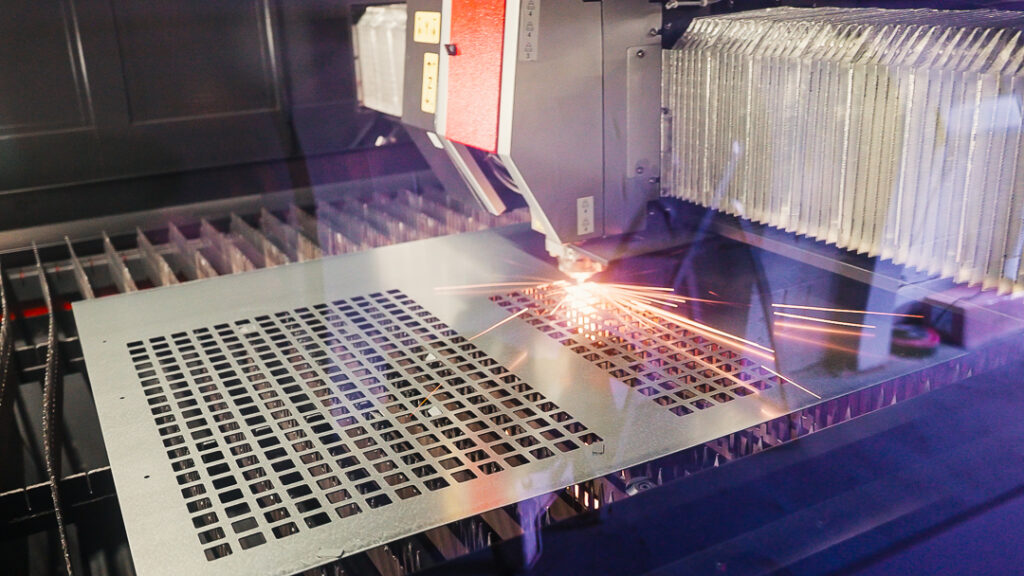

4. Reduced Waste and Higher Material Utilisation

Because laser cutting works directly from CAD designs, the nesting of parts can be optimised to limit scrap. This approach reduces material waste and supports more sustainable manufacturing processes.

Our laser cutters’ ability to create detailed shapes without the need for extensive tooling also means fewer offcuts and greater yield from each sheet of material.

5. Consistent Quality and Repeatability

Manufacturers rely on laser cutting for its ability to produce identical parts repeatedly. Once a design is programmed, every component is cut to the same high standard, helping maintain quality across production runs and simplifying assembly.

This reliability is one of the reasons laser cutting is widely used for batch manufacturing, replacement parts, and precision fabrication across diverse industries.

Why Choose Northwest Waterjet for Laser Cutting?

Northwest Waterjet provides a professional laser cutting service supported by expert CAD design capabilities and advanced laser cutting machinery. Whether you need fast lead times, custom one-off components, or ongoing manufacturing support, our team ensures every project meets the highest standards of accuracy and finish.

Our services offer the ideal balance of quality, flexibility, and efficiency. Contact us today for more information.