What is Laser Cutting and How Does It Work?

Laser cutting has become an essential manufacturing process for creating accurate, high-quality components across a wide range of materials. But what exactly is laser cutting, and how does it work?

An Introduction To Laser Cutting?

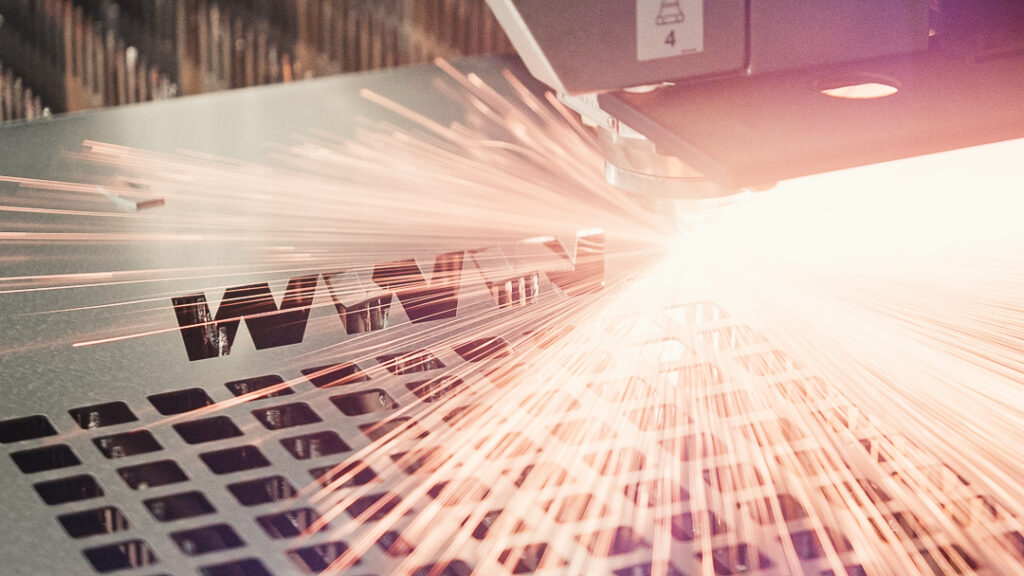

Laser cutting is a technology that uses a high-powered laser beam to cut through materials with precision. It’s widely used in industries such as automotive, aerospace, and construction due to its ability to produce clean, intricate slices at high speeds while generating minimal material waste.

Unlike traditional cutting methods that rely on blades or tools, laser cutting is a non-contact process, meaning there is minimal wear and tear, reducing downtime and maintenance costs, and making laser cutting an efficient cutting process.

How the Laser Cutting Process Works

The process involves directing a laser beam, typically generated using CO₂, fibre, or crystal lasers, onto the surface of a material.

The beam is focused through a lens, which increases its intensity to the point where it can melt or burn the target, causing cuts or engravings.

Learn more about the science behind laser technology on HowStuffWorks.

Here’s a breakdown of how the process works:

- The design is input, a CAD (Computer-Aided Design) file is used to define the shape and dimensions of the cut.

- The laser source produces a beam, which is then guided to the cutting head.

- The beam heats the material locally, causing it to melt or combust, while a jet of gas blows the molten material away.

- CNC (Computer Numerical Control) systems guide the laser across the surface with extreme accuracy, following the design.

Benefits of Laser Cutting

- Precision: Laser cutting has the ability to make intricate and highly detailed cuts.

- Speed: Faster than many traditional cutting methods.

- Versatility: Works on a variety of materials. For more detailed guidance on what materials can and can’t be laser cut, click here.

- Minimal Waste: High levels of precision and narrow kerf width mean less material is lost during cutting.

Laser Cutting vs. Water Jet Cutting

While laser cutting excels at speed and precision, water jet cutting offers unmatched versatility through its ability to cut through a wider variety of materials, including heat-sensitive ones, without causing thermal distortion.

If you’re working with thicker metals, composites, or stone, a water jet cutting machine is often the better choice, with no risk of burnt edges or material hardening.

Check out our blog ‘Waterjet vs. Laser Cutting: Which is right for your project?’ for more information.

Our team can help you decide the best solution for your project. With extensive experience and state-of-the-art machinery, North West Waterjet delivers results that are both precise and cost-effective.

Contact us today for a free consultation or quote and experience the cutting edge of precision.